Operate Phase

- Operate Phase

- Process Simulation & Modeling

- Relief and Flare System Assessment

- Asset Management Services

- Dynamic Simulations

- Gas Processing

- Technical Safety Services

Special Services

The concept phase of the project is all to do with an OPPORTUNITY which may nurture further as a project. It hasbeen always challenging throughout the project lifecycle whether its new field development, new pilot facility, new plant, or major process expansion etcas it has more questions than answers and more assumptions than data. EngiMates works as an extended partner with our clients in identifying and selecting the concepts for projects as we very well understand the implications of these uncertainties.

EngiMates Concept Team confirms technical and economic feasibility of the opportunity proposed by client and identify the most preferred method of its implementation. We perform the study, identify the options, and rank the options based on technical merits, HSE, system reliability, economics (NPV, CAPEX - OPEX), and any other business value drivers.The team then selects the most promising solution, details out the scope of work and prepares a cost estimate.

EngiMatesutilizes a unique methodology & approach in concept development phase which enable us to stand up distinctively and deliver value driven product to our clients.

The concept phase of the project is all to do with an OPPORTUNITY which may nurture further as a project. It hasbeen always challenging throughout the project lifecycle whether its new field development, new pilot facility, new plant, or major process expansion etcas it has more questions than answers and more assumptions than data. EngiMates works as an extended partner with our clients in identifying and selecting the concepts for projects as we very well understand the implications of these uncertainties.

EngiMates Concept Team confirms technical and economic feasibility of the opportunity proposed by client and identify the most preferred method of its implementation. We perform the study, identify the options, and rank the options based on technical merits, HSE, system reliability, economics (NPV, CAPEX - OPEX), and any other business value drivers.The team then selects the most promising solution, details out the scope of work and prepares a cost estimate.

EngiMatesutilizes a unique methodology & approach in concept development phase which enable us to stand up distinctively and deliver value driven product to our clients.

EngiMates Concept Engineering Package includes deliverables as follows:

- Preliminary Process Design Basis

- Process Alternatives Evaluations Summary

- Process Simulation and Heat and Material Balance Data

- Process Flow Diagrams (PFDs)

- Equipment List

- Utility Load List

- Major Equipment Conditions of Service List

- Capital and Operating Cost Estimate (+40% /-30%)

- Summary of Raw Materials and Utility Requirements

- Project Cost Plans & Schedule

- Value Assurance Reviews.

- Project Interface Register

- Process Risk Summary.

- Project Report.

Engineering Services (FEED, DD & EPC)

EngiMates provides multi-discipline engineering servicesfor front-end engineering design (FEED), Detailed Design (DD) & EPC phase. Our team is well-competent in all aspects of engineering services and we provide complete engineering solutions to our clients. EngiMates provide following multidiscipline services during Design & Engineering Phase:

Concept & Process

- Process & System Design

- Process Simulations & Modelling

- Heat & Material Balance

- PFD, P &ID, MSD, PSD

- Equipment sizing & datasheets.

- Equipment & Instruments Specs

- Hydraulic Designs

- HAZID, HAZOP, SIL

- Control & Safeguarding philosophy & narratives

- Flare & relief system analysis

- Process Drafting

Mechanical (Static & Piping)

- Pressure Vessel Design, Modification, And Rerate

- Tank Design and Modification

- Exchanger Thermal Design

- Packaging Units Design and Equipment Specification

- Equipment Selection and Specification

- Contractor And Vendor Document And Bid Review

- Plot Plan & Piping Layout

- Piping Specifications

- Stress Analysis

- 3D Modelling (PDM/PDS)

- Mechanical Drafting

Electrical

- Power System Engineering And Design

- Short Circuit And Load Flow Studies

- Motor Starting Studies

- Arc Flash

- Single Line Development

- Electrical Equipment And Substation Layouts

- Substation Design

- Switchgear & MCC

- Protection System

- Cathodic Protection

- Grounding And Lightning Protection Systems

- Electrical Drafting

Instrumentation & Controls

- Loop & Logic Diagrams

- Instrument LocationPlans & Field Wiring

- Installation & Mounting Details

- I/O And Instrument Listing

- Cable Schedule

- Cabinet Wiring And Layouts

- Control Schematics

- PLC/DCS Specifications

- Functional Control Descriptions

- Factory Acceptance Tests

- Control System Architectures

- I &C Drafting

Civil

- Site Preparation

- Concrete & Steel Structure design

- Evaluation Of Existing Structures

- Design For Explosion Control

- Design For Spill Containment

- Building Safety Analysis

- Drainage Plans And Structures

- Road Layouts & Paving Design, Parking Facilities

- Civil Drafting

Project, Procurement & Construction Management

- Bid Tabulation & Evaluation

- Expediting

- Procurement Package Preparation

- Project Procurement Strategy & Management

- Constructability Reviews

- Reliability/Operability Reviews

- Contractor Pre-Qualifications

- Turnarounds

- Construction Management

- Start-Up & Commissioning

The field / facility operate phase has always been challenging as the engineering project lifecycle does not foresee operational issues and asset management plans in details. EngiMates personnel wide experience in operation & asset management bridge these gaps between engineering & operation project lifecycle. We provide detailed attention to client’s specific requirements with pragmatic approach to deliver improved long term solutions. EngiMates provides special services during Operate Phase.

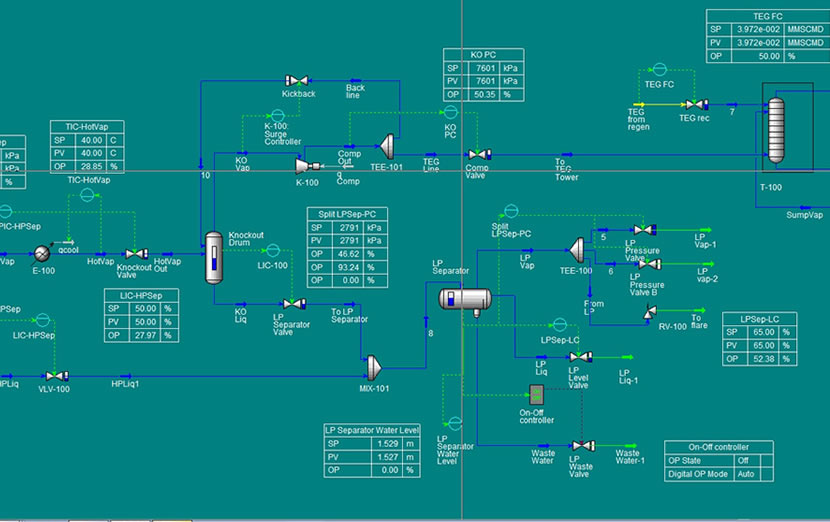

Process Simulations & Modeling

- Development of Process Simulation Models with world class recognized simulation softwares.

- Modeling facilities/operating plants with the current operating conditions & accurate components characterization methods via process simulation models to determine bottlenecks, operating envelopes & troubleshoot the operating plant problems.

- Steady state & Transient analysis for complex system hydraulics to determine the adequacies, capacities & constraints, surge & slug analysis in the pipelines.

- Design/Rating/Evaluation of Heat Exchangers via renowned exchanger suite application programs.

- Development of Flare Network & Flare header sizing through Flare sizing softwares.

- Process Simulation Training to Operating & Engineering companies.

Relief and Flare System Assessment

A well designed relief system may protect the equipment, process system and the operating plant during any catastrophic event. However, it is essential to have proper experience and knowledge to design an adequate relief system.

A well designed relief system may protect the equipment, process system and the operating plant during any catastrophic event. However, it is essential to have proper experience and knowledge to design an adequate relief system.

Engimates team members previous work experiences possess excellent knowledge of ANSI/API/ISO standards, Client design engineering practices, Specific refinery guidelines and expertise in using PSPPM, Aspentech Safety Analysis, and spreadsheets tools. This brings uniqueness to EngiMates relief system design and analysis services.

We provide following services for Relief System (PSV) Analysis:

- Process simulation modeling at normal operating plant conditions and relief conditions for fractionators / column system, heat exchangers, compressors, turbines, vessels etc. in Aspentech HYSYS, Aspen Plus and Honeywell UNISIM.

- Adequacy check of refinery relief & flare systems based on the refinery specific guidelines, OSHA, API-520/521/2000 standards using client proprietary software or EngiMates validated Excel Spreadsheet Tools.

- Data collection

- Define the system/equipment to be protected

- Input Equipment/system and Relief Device information

- Define all overpressure scenarios

- Calculate relief rate for applicable scenarios

- Size relief device for all applicable scenarios

- Complete commenting forms and discussion list.

- Develop mitigation options for inadequate relief devices, high inlet & outlet pressure drop concerns and other concerns.

- Developed project report / discussion list for the concerns identified & their mitigations.

We provide following services for Flare and Blowdown Study:

- Assessment of the spill to flare valves

- Identification of the governing scenario for every spill-to-flare valve in the plant and calculation of the minimum fluid and material temperature in the flare system.

- Calculation of the minimum temperature for scenarios such as normal operation, start-up, cold restart, hydrate formation etc.

- Assessment of the blowdown systems

- Identification of the blowdown scenarios (fire ESD, adiabatic and maintenance blowdown) for every blowdown valve in the plant and calculation of the minimum fluid and material temperature in the flare system.

- Calculation of the minimum temperature for scenarios such as normal operation, start-up, cold restart, maintenance blowdown, hydrate formation etc.

- Confirmation blowdown system meets relevant depressurizing criteria.

- Confirmation that the material is adequate for the low temperatures.

- Flare Adequacy Study

- Develop Flarenet model of exiting plant in Aspen Flare System Analyzer.

- Identify governing scenarios for HP Flare and maximum loads.

- Perform adequacy study on all parts of the Flare System, including sub-headers, headers, Flare Knock-Out Vessel, flare stack and Flare tip

Asset Management Services

- Complete Plant data evaluation and process optimization of operating facilities.

- Process Simulation modeling of facility to evaluate facility up-gradation requirement, bottlenecks determination & capacity evaluation.

- Operation Troubleshooting & mitigations of complete facilities.

- Drafting of Red Line Mark ups.

- As Building of existing facilities.

Dynamic Simulations

EngiMates offers an exclusive blend of knowledge to deliver bespoke, rigorous solutions that provide clear and feasible design and operational recommendations.- Design validation for complete process and control schemes

- Overpressure protection (HIPPS)

- Analyse transient scenarios

- Flare header capacity validation

- Validating operational /start-up procedures

- Dynamic depressurization studies

Gas Processing Studies

- Amine Unit Solvent Selection Studies.

- Sour Gas Sweetening Technology Selection Studies.

- Amine and TEG unit process optimization studies.

Technical Safety Services

- Facility Design Review Support

- Retrospective HAZOP / SIL Facilitation.

- Fire Explosion, radiation, dispersion studies.

- Physical effects modeling