Energy consumption is one of the largest operating costs in oil and gas refineries. Rising…

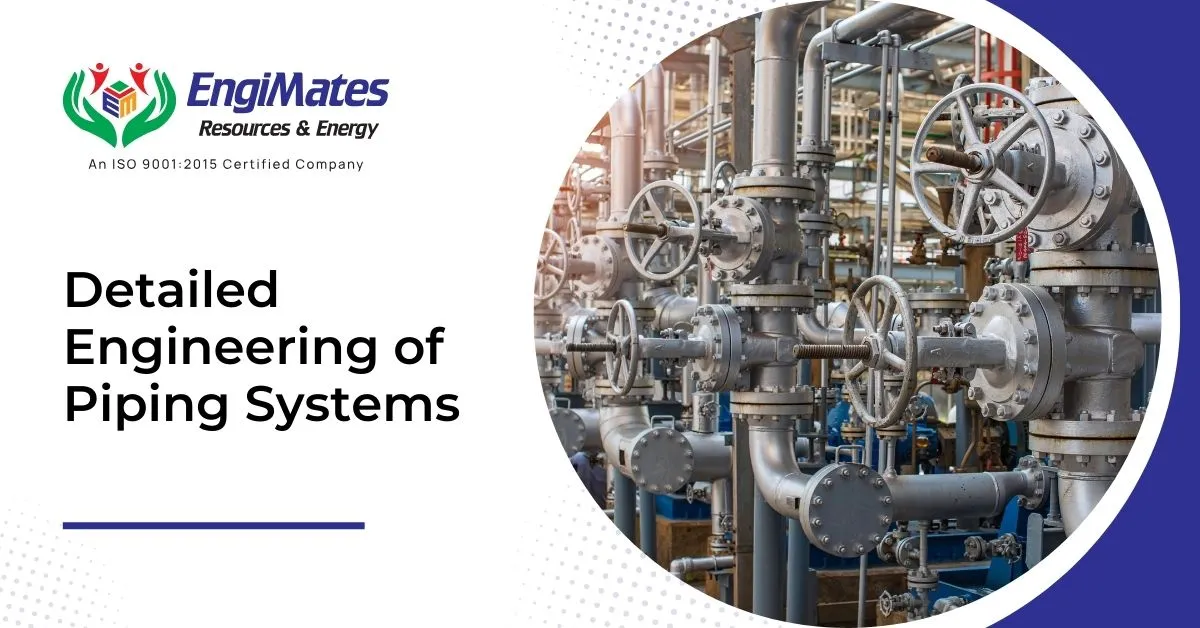

In the world of industrial engineering, detail engineering for pipes plays a pivotal role in ensuring the successful execution of various projects, particularly in industries such as power, chemical, and manufacturing. It involves the meticulous design, layout, and specification of every component that makes up the piping infrastructure. This stage ensures that all piping systems are not only functional but also safe, efficient, and durable, helping to prevent costly errors during construction or operation.

What is Detailed Engineering in Piping?

Detail engineering for pipes refers to the final phase of the engineering design process, which transforms preliminary designs into construction-ready plans. This includes defining precise specifications for pipes, valves, pumps, supports, and other components while ensuring compliance with industry standards. Additionally, detailed engineering involves creating essential documents like piping and instrumentation diagrams (P&IDs), isometric drawings, and fabrication drawings, which are crucial for accurate construction and installation.

The Role of Piping Engineering in Detailed Design

Piping engineering is central to the detailed engineering phase. This discipline focuses on ensuring that all aspects of the piping system—such as layout, materials, and dimensions—are designed in accordance with the project requirements. It involves the analysis of factors such as fluid flow, pressure drop, and thermal expansion, ensuring the system operates efficiently under varying conditions. Engineers collaborate with designers and draftsmen to create a detailed blueprint that guides construction, reducing the risk of errors or rework during the build phase.

Key Steps in the Detailed Engineering Process

- Procurement and Equipment Selection:

During this phase, engineers determine the specifications for pipes, valves, and fittings, and select appropriate materials based on factors like pressure, temperature, and the nature of the fluid being transported. - Thermal and Stress Analysis:

Detail engineering for pipes also involves conducting thermal ratings for heat exchangers and performing stress analysis on the pipes. This ensures that the system can handle operational stresses, temperature variations, and pressure fluctuations without failure. - Piping and Instrumentation Diagrams (P&ID):

P&IDs are crucial documents created in the detailed engineering phase. These diagrams illustrate the flow of materials through the system and show the connections between different pieces of equipment, piping, and instrumentation, ensuring that the entire system is integrated and functional. - Development of Detailed Drawings:

Detail engineering for pipes also includes the creation of construction-ready drawings, such as isometric piping drawings, that provide clear instructions for fabrication and assembly. These drawings help in visualizing the entire system before construction begins.

Piping Engineering: Evolution and Technological Advancements

In the past, detailed piping engineering was often done manually, which was time-consuming and prone to errors. However, with the advancement of technology, particularly the introduction of 3D modeling and Computer-Aided Design (CAD), the process has become significantly more accurate and efficient. Modern engineering tools allow for virtual simulations of piping systems, helping identify potential issues before they arise on the construction site. These tools enhance the precision of designs and reduce the likelihood of costly mistakes.

Looking for expert piping engineering services? Contact us today to ensure precise design and efficient implementation for your next project!

The Importance of Outsourcing Piping Engineering

Outsourcing detail engineering for pipes can be a cost-effective solution for many organizations. By partnering with experienced engineering firms, companies can access expert knowledge and cutting-edge technology without having to invest in in-house resources. This also allows for faster project completion, as specialized engineers can take care of the intricacies involved in piping design, enabling companies to focus on their core competencies.

Benefits of Detailed Piping Engineering

- Improved Efficiency:

Detail engineering for pipes ensures that every aspect of the piping system is designed for optimal flow and performance, reducing operational inefficiencies. - Cost-Effectiveness:

By identifying potential issues early in the design process, detailed engineering helps reduce costly revisions and ensures that projects stay within budget. - Safety and Compliance:

Detail engineering for pipes ensures that systems comply with industry standards and regulations, which is critical for maintaining safety and avoiding legal complications. - Optimized Project Timelines:

Detailed engineering reduces the likelihood of delays by providing clear instructions for construction, ensuring that the project progresses on schedule.

Frequently Asked Questions

What is the basic concept of piping engineering?

Piping engineering involves the design, layout, and installation of piping systems for the transport of fluids, ensuring safety, efficiency, and compliance with industry standards.

What are the basics of a piping system?

A piping system consists of pipes, valves, fittings, supports, and instrumentation used to transport fluids or gases within industrial applications, designed for functionality and safety.

What are the different types of piping engineers?

Piping engineers include design engineers, stress engineers, installation engineers, and maintenance engineers, each specializing in different aspects of piping systems, such as design, stress analysis, and operation.

Conclusion

Detail engineering for pipes is a crucial step in the design and construction of efficient, safe, and durable piping networks. By ensuring that all components are properly specified and integrated, detailed engineering helps avoid costly errors, improve system performance, and ensure regulatory compliance. Whether done in-house or outsourced, investing in detailed engineering ensures that the final piping system meets the highest standards of quality and functionality.